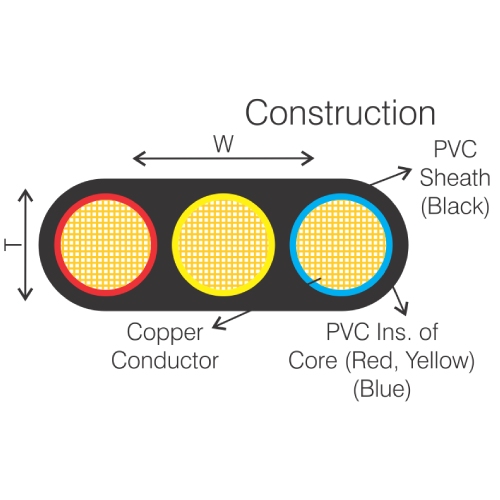

Radicab 3 Core Submersible Cables are manufactured keeping in mind the severe and difficult conditions in which they are required to perform. The individual conductors are made from bright electrolytic grade copper. The wires are drawn, annealed and bunched properly to ensure flexibility and uniform resistance. Each of the three copper conductors is insulated with a special PVC compound formulated and manufactured In-house. The cores are laid up in flat parallel / round PVC compound formulated and manufactured in-house. The cores are laid up in flat parallel / round position. The outer sheath of the cable is made from a special grade of abrastant PVC compound impervious to water, grease, oil, etc.

Unique features:

- Tough & flexible cable with exceptional moisture.

- Safe, reliable with excellent wet electrical properties.

- Good insulation properties when submerged in water.

- Excellent mechanical & electrical properties.

- Working voltage - 1100 Volt.

- Progressive sequential length marking on every meter.

- Conductor - bright annealed 99.97% pure bare copper.

- Outer sheath comprises of highly abrasion resistant PVC.

- Color of cores - Red, Yellow, Blue compound impervious to grease, oil and water etc.

- Available in drums of cable length 500 mtr +/- 5%.

- Best quality of electrolytic grade copper.

- Cable also available in 100 mtr length.

Applications

To supply power to submersible pumps in deep bore well for:

- Irrigations

- Fountains

- Drinking water supply

- Offshore drilling rigs

- Mine dewatering

- Sewage treatment plants

- Industries

- Sea water filtration plants

- Swimming pools

- Aquariums

Table: Technical Specifications

| Nominal Cross Sectional area of conductor | Number/Nom. Dia of cond. Strands | Thickness of Insulation (Nom) | Thickness of Sheath (Nom) | Sheath Approx Overall Dimension | Max Conductor Resistance at 20°C (Max.) | Current Carrying Capacity at 40°C | |

|---|---|---|---|---|---|---|---|

| Width (W) | Height (H) | ||||||

| sq. mm. | mm | mm | mm | mm | mm | Ohm/Km | Amps. |

| 1.50** | 22/0.30 | 0.6 | 0.9 | 10.1 | 4.7 | 12.1 | 13 |

| 2.50** | 36/0.30 | 0.7 | 1.0 | 12.2 | 5.5 | 7.41 | 18 |

| 4.00 | 56/0.30 | 0.8 | 1.0 | 14.6 | 6.5 | 4.95 | 24 |

| 6.00 | 84/0.30 | 0.8 | 1.1 | 16.2 | 7.0 | 3.30 | 31 |

| 10.00 | 80/0.40 | 1.0 | 1.4 | 20.2 | 8.5 | 1.91 | 42 |

| 16.00 | 126/0.40 | 1.0 | 1.4 | 23.4 | 9.7 | 1.21 | 57 |

| 25.00 | 196/0.40 | 1.2 | 2.0 | 28.5 | 11.7 | 0.780 | 72 |

| 35.00 | 276/0.40 | 1.2 | 2.0 | 32.1 | 13.0 | 0.554 | 90 |